New busbar trunking system increases the efficiency of wind turbines

Siemens' new LDM busbar trunking system increases the efficiency of wind turbines

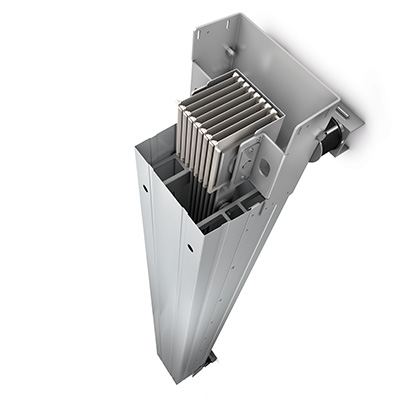

The LDM system from the Sivacon 8PS product family will replace cables for transmitting power from the generator to the grid infeed. The fast, cost-efficient installation and the increased efficiency with less power loss make construction as well as operation of a wind turbine more efficient and profitable. The low fire load achieved by not using plastics and standards-compliant design verification increase the turbines' operational safety. The system is now designed for a rated current of 800 to 8200 amperes.

The new maintenance-free and fail-safe busbar trunking system is an enhancement of the existing LD system. Optimized cross-sections enabled the efficiency to be significantly improved, which in turn decreases power loss. This means additional feed-in compensations for the plant operator throughout a wind turbine's service life. In contrast to using cables, the LDM busbar trunking system can be pre-installed in the individual tower segments during the construction phase, which saves both time and costs. As the wind turbine is assembled, the individual busbar elements of the various segments are connected by a segment connector using a standard tool and only one bolt. The substantially wider fixing distances compared to cable installations speed up the installation of the new system and reduce the space and material needed. Thanks to a special design of the busbars, manufacturing tolerances can be compensated at the tower's segment transitions; joint brackets with damper elements protect the system in case of tower movements.

The LDM busbar trunking system meets the new IEC 61439-1/-6 standard that requires design verification of the system. This ensures that the specified technical parameters are permanently fulfilled. Further parameters, such as the required short-circuit ratings, can be easily met by means of suitable dimensioning and engineering. If needed, the system can be connected directly to the switchboard at the base of the tower and via separate cable infeeds to other equipment and to the loop cable. The LDM busbar trunking system satisfies a IP21 degree of protection and is thus suited for use in moisture- and salt-laden air.

For further information on busbar trunking systems SIVACON 8PS, please see www.siemens.com/busbar

Siemens AG (Munich, Germany), is a global powerhouse in electronics and electrical engineering, operating in the fields of industry, energy and healthcare as well as providing infrastructure solutions, primarily for cities and metropolitan areas. For over 165 years, Siemens has stood for technological excellence, innovation, quality, reliability and internationality. The company is one of the world's largest providers of environmental technologies. Around 43 percent of its total revenue stems from green products and solutions. In fiscal 2013, which ended on September 30, 2013, revenue from continuing operations totaled €74.4 billion and income from continuing operations €4.2 billion. At the end of September 2013, Siemens had around 362,000 employees worldwide on the basis of continuing operations. Further information is available on the Internet at: http://www.siemens.com/infrastructure-cities

The Siemens Low and Medium Voltage Division (Erlangen, Germany) serves the entire product, system, and solutions business for reliable power distribution and supply at the low- and medium-voltage levels. The Division's portfolio includes switchgear and busbar trunking systems, power supply solutions, distribution boards, protection, switching, measuring and monitoring devices as well as energy storage systems for the integration of renewable energy into the grid. The systems are supplemented by communications-enabled software tools that can link power distribution systems to building or industry automation systems. Low and Medium Voltage ensures the efficient supply of power for power grids, infrastructure, buildings, and industry. Additional information is available on the Internet at: http://www.siemens.com/low-medium-voltage

Reference Number: ICLMV20140701e

Contact

Mr. Heiko Jahr

Low and Medium Voltage Division

Siemens AG

Freyeslebenstr. 1

91058 Erlangen

Germany

Tel: +49 (9131) 7-29575

Alle Nachrichten aus der Kategorie: Unternehmensmeldungen

Neueste Beiträge

Diamantstaub leuchtet hell in Magnetresonanztomographie

Mögliche Alternative zum weit verbreiteten Kontrastmittel Gadolinium. Eine unerwartete Entdeckung machte eine Wissenschaftlerin des Max-Planck-Instituts für Intelligente Systeme in Stuttgart: Nanometerkleine Diamantpartikel, die eigentlich für einen ganz anderen Zweck bestimmt…

Neue Spule für 7-Tesla MRT | Kopf und Hals gleichzeitig darstellen

Die Magnetresonanztomographie (MRT) ermöglicht detaillierte Einblicke in den Körper. Vor allem die Ultrahochfeld-Bildgebung mit Magnetfeldstärken von 7 Tesla und höher macht feinste anatomische Strukturen und funktionelle Prozesse sichtbar. Doch alleine…

Hybrid-Energiespeichersystem für moderne Energienetze

Projekt HyFlow: Leistungsfähiges, nachhaltiges und kostengünstiges Hybrid-Energiespeichersystem für moderne Energienetze. In drei Jahren Forschungsarbeit hat das Konsortium des EU-Projekts HyFlow ein extrem leistungsfähiges, nachhaltiges und kostengünstiges Hybrid-Energiespeichersystem entwickelt, das einen…