More process control during laser-based CFRP processing

The laser cutting process with a robot enables a flexible processing of 3D parts. Photo: LZH

Parts made of CFRP are especially well suited for the automotive and aviation industry, because they not only enable a significant weight reduction. In addition, this material has a very high strength and stiffness.

However, since the processing of this material requires a lot of expertise, it is so far, apart from the aviation industry, mainly used in sports cars and small series automobiles. In the future, not only larger series shall be possible, but also the cost-efficient production of individual parts shall be promoted. Therefore, the LZH is working on optimizing the process control in various projects.

Flexible processing with new handling systems

The Composites Group of the Production and Systems Department of the LZH is developing new processes for the flexible and automated processing of CFRP and glass fiber reinforced plastics (GFRP). Here, the use of industrial robots and multi-axis systems combined with novel laser beam sources enables the individual processing of 3D parts and large-scale semi-finished parts – both for cutting and ablation as well as for welding.

Besides the flexible processing of different parts, the process control is another important aspect. For example during laser transmission welding, different techniques are used for the temperature-based process control in order to achieve a constant high quality of the welding result.

Also for the cutting of composite components various temperature control methods are used to optimize the process and to guarantee a constant processing quality. When removing defective areas as preparation for repair, it is necessary to do this step by step. Here too, the LZH is working on processes for a reliable machining.

At the Hannover Messe, the LZH is presenting the latest developments for the laser processing of carbon fiber reinforced plastics. Visit us at the Pavilion of the State of Lower Saxony in hall 2 at stand A08!

Media Contact

Weitere Informationen:

http://www.lzh.de/Alle Nachrichten aus der Kategorie: Messenachrichten

Neueste Beiträge

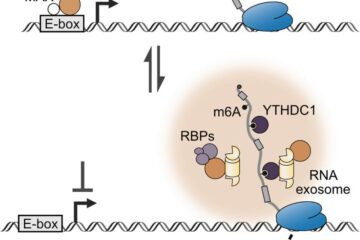

Forschende enthüllen neue Funktion von Onkoproteinen

Forschende der Uni Würzburg haben herausgefunden: Das Onkoprotein MYCN lässt Krebszellen nicht nur stärker wachsen, sondern macht sie auch resistenter gegen Medikamente. Für die Entwicklung neuer Therapien ist das ein…

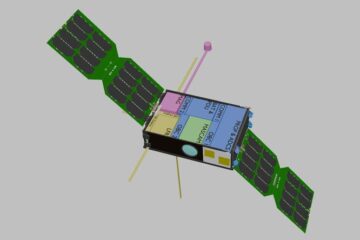

Mit Kleinsatelliten den Asteroiden Apophis erforschen

In fünf Jahren fliegt ein größerer Asteroid sehr nah an der Erde vorbei – eine einmalige Chance, ihn zu erforschen. An der Uni Würzburg werden Konzepte für eine nationale Kleinsatellitenmission…

Zellskelett-Gene regulieren Vernetzung im Säugerhirn

Marburger Forschungsteam beleuchtet, wie Nervenzellen Netzwerke bilden. Ein Molekülpaar zu trennen, hat Auswirkungen auf das Networking im Hirn: So lässt sich zusammenfassen, was eine Marburger Forschungsgruppe jetzt über die Vernetzung…