Heraeus Innovation Awards 2008: Infrared emitter with white nano reflector named best innovation of 2008

Heraeus Innovation Award 2008 (from left): Dr. Frank Heinricht, Wolfgang Schmitt (3rd place), Jürgen Weber (1st place), Danny Habets (2nd place), Dr. Jürgen Heraeus and Dr. Wulf Brämer (Heraeus Innovation Management) (Photo: Heraeus)

The developments recognized at the 2008 Heraeus Innovation Awards include an innovative infrared emitter with a white reflector made of opaque quartz glass that can be used in a vacuum at high temperatures; a new, highly sensitive oxygen sensor used to measure oxygen in ppb (parts per billion) during the manufacture of compacted graphite iron (CGI); and a new solder paste compound for silver contacts in power electronics components.

Top honors went to Jürgen Weber (Heraeus Noblelight / Heraeus Quarzglas) at last night’s ceremony in Hanau. Danny Habets of Heraeus Electro-Nite won second place and Wolfgang Schmitt of the W. C. Heraeus Contact Materials Division took third. The prizewinners received a gold medal commemorating the award from Dr. Jürgen Heraeus, Chairman of the Supervisory Board and patron of the event, and Dr. Frank Heinricht, Chairman of the Board of Management.

Dr. Frank Heinricht praised this year’s prize winners: “They reacted directly and successfully to the market’s changes and demands by developing innovative products, and succeeded in opening up new market segments in the process. This is very important in economically difficult times.” Heraeus currently holds more than 4,900 patents, and invests more than € 60 million in research and development. Over 350 R&D employees in 25 development centers around the world fuel the innovative engines. The Heraeus Innovation Award was launched in 2003. All Heraeus researchers and developers worldwide are eligible to participate. Heraeus conceived the Innovation Award to make innovations that are often hidden in the company visible to everyone and at the same time, to honor the achievements and talents of the researchers and developers.

1st place: Infrared emitter with a white nano reflector (QRC® reflector)

The infrared emitter with the new QRC® reflector (QRC = quartz reflective coating) developed by Jürgen Weber and a team of experts from Heraeus Noblelight and Heraeus Quarzglas has many applications, such as improving energy efficiency in solar cell production for the photovoltaic industry. Certain steps in the cell production process must be performed in a vacuum at temperatures up to 1200°C. Vacuum heating using the white nano reflector made of opaque glass involves no contact and therefore does not carry the risk of impurities. Utilizing high-purity quartz materials minimizes the possibility of contamination, as would be the case with metal reflectors.

Solar cells should convert solar energy as efficiently as possible. An anti-reflex coating substantially improves the absorption rate for solar cells. This coating is applied under a vacuum at very high temperatures. Emitters equipped with a white nano reflector have a highly diffused reflection factor, which helps stabilize and optimize heating processes in solar cell manufacturing by maintaining process parameters such as temperature and homogeneity. This reduces costs while increasing energy efficiency in the photovoltaic system. Due to its special nano and microstructure, the globally-patented reflector reflects a broad spectrum of light ranging from the ultraviolet to infrared wavelengths, ushering in new areas of application, including, for processing plastic components and UV curing in the semiconductor industry.

2nd place: ppb oxygen sensor for the cast-iron industry

Danny Habets and Heraeus Electro-Nite have three years of R&D invested in their innovative ppb sensor. Refinements in measurement technology have enabled this highly sensitive sensor to measure oxygen in the ppb range (ppb = parts per billion), making it a thousand times more sensitive than Heraeus’ best sensor to date. The sensor is used for controlling processes in compacted graphite iron (CGI) production, a material needed for the next generation of lighter diesel motors. CGI possesses a special graphite structure that makes it extremely durable and stable. It can withstand extreme temperatures and is easy to cast. The material is in high demand as an alternative to aluminum for use in high-temperature components for internal combustion engines. To create this specific graphite structure, tiny amounts of magnesium are added during production along with carbon and silicon. An admixture of 70 to 150 ppm (ppm = parts per million) is required to achieve the desired stabilizing structure. The Heraeus sensor measures the oxygen content directly in the cast iron melt by means of a chemical reaction between the magnesium and oxygen. This in turn is used to determine the exact magnesium content. Previous methods of measuring magnesium content required a costly and time-consuming sampling process. By contrast, the ppb sensor can determine the correct value in a single measurement within 12 seconds. This saves users a significant amount of time, money and energy.

3rd place: New silver contact as a lead-free solder replacement for power electronics

Endowed with excellent thermal and electrical conductivity, the precious metal silver has proven itself worthy as a contact material for power electronics components. But up to now, the industry has lacked efficient processes for connecting contact surfaces using a silver layer. Wolfgang Schmitt of W. C. Heraeus has developed both a silver contact paste and a process for creating these silver layers. The pastes contain special silver compounds which release elemental silver during the joining process. This enables Schmitt’s innovative method to create extremely homogenous silver layers, which previously could only be achieved with pressure sintering or nano silver pastes. These new silver contact pastes are significantly more stable than the nano silver used in the past.

Power electronics play a key role in industrial electric motors, motor vehicles and no-break power supply systems. The market for power modules is growing by more than 7% annually. In environmentally-friendly hybrid vehicles, for example, power electronics help convert electrical energy to the proper voltage and frequency for the electric motor. Materials used for power electronics must meet extremely high performance requirements, especially for integrated circuits, because voltages can climb to several thousand volts and currents can reach several thousand amps. This new silver contact as a lead-free solder replacement expands Heraeus’ product portfolio for integrated circuit and mounting technologies for power electronics.

For a more detailed report on the 2008 Innovation Award ceremony and the prize-winning products, please see teamwork issue 121 and the next edition of technology report.

Media Contact

Weitere Informationen:

http://www.heraeus.comAlle Nachrichten aus der Kategorie: Förderungen Preise

Neueste Beiträge

Merkmale des Untergrunds unter dem Thwaites-Gletscher enthüllt

Ein Forschungsteam hat felsige Berge und glattes Terrain unter dem Thwaites-Gletscher in der Westantarktis entdeckt – dem breiteste Gletscher der Erde, der halb so groß wie Deutschland und über 1000…

Wasserabweisende Fasern ohne PFAS

Endlich umweltfreundlich… Regenjacken, Badehosen oder Polsterstoffe: Textilien mit wasserabweisenden Eigenschaften benötigen eine chemische Imprägnierung. Fluor-haltige PFAS-Chemikalien sind zwar wirkungsvoll, schaden aber der Gesundheit und reichern sich in der Umwelt an….

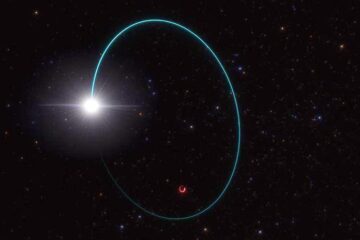

Das massereichste stellare schwarze Loch unserer Galaxie entdeckt

Astronominnen und Astronomen haben das massereichste stellare schwarze Loch identifiziert, das bisher in der Milchstraßengalaxie entdeckt wurde. Entdeckt wurde das schwarze Loch in den Daten der Gaia-Mission der Europäischen Weltraumorganisation,…